The manufacturing landscape is constantly evolving, and automation is at the forefront of the transformation. specifically, automated liquid filling is revolutionizing industries by enhancing effectiveness, precision, and Total productivity. Choosing the proper liquid filling device available for purchase is vital for companies planning to continue to be competitive and fulfill the rising demands of the marketplace. This article will explore the latest innovations in liquid filling equipment, highlight the importance of picking the correct manufacturer, and provide advice on selecting the ideal product in your unique sector application.

Table of contents:

improvements in Liquid Filling Machines: What major producers provide in 2025

Why deciding on the correct Liquid Filling equipment Manufacturer Impacts Your Output excellent

Liquid Filling Machine for Sale: Which Model matches Your Industry Application Best?

Innovations in Liquid Filling devices: What major Manufacturers offer you in 2025

Leading liquid filling device manufacturer are frequently pushing the boundaries of know-how, introducing innovative functions that increase general performance and effectiveness. one particular important development is The mixing of Highly developed sensor technological know-how, enabling actual-time checking of fill concentrations and automated changes to take care of accuracy. Yet another substantial innovation is the development of a lot more adaptable equipment that can handle a wider variety of liquid viscosities and container measurements, decreasing the need for many devices. enhanced cleaning and sterilization techniques are getting prominence, notably in industries with rigorous here hygiene requirements. In addition, manufacturers are incorporating intelligent know-how, making it possible for for remote checking, diagnostics, and predictive maintenance, reducing downtime and maximizing productivity. using robotics and automation is usually on the rise, enabling fully automatic filling traces with small human intervention. When evaluating different machines, contemplate these innovations and decide on a product that includes the latest technological innovation to improve your generation processes.

Why Choosing the appropriate Liquid Filling equipment company Impacts Your Output high-quality

picking the best liquid filling machine maker incorporates a profound impact on your output high-quality. A respected producer not merely presents substantial-quality devices but also provides knowledge, guidance, along with a determination on your achievements. A major-tier producer will operate closely with you to grasp your particular needs and suggest by far the most suitable options. they'll offer personalized device configurations to enhance your output procedures and assure consistent, precise filling. Additionally, a dependable producer will supply extensive instruction and technological assistance to ensure your devices run efficiently and competently. In the party of a problem, they are going to deliver prompt and reliable fix services to attenuate downtime. By partnering that has a dependable producer, you obtain use of a wealth of information and practical experience that will help you help your product or service top quality, lower squander, and improve your Over-all operational efficiency. It’s essential to consider things such as certifications and industry name when building your final decision.

Liquid Filling Machine for Sale: Which design suits Your market Application Best?

Finding the proper liquid filling device on the market necessitates careful consideration of your particular marketplace application. diverse industries have distinctive wants, and The best equipment will differ based on the variety of liquid getting stuffed, the container size, and the specified creation price.

Pharmaceuticals: involve machines with high precision, sterilization capabilities, and compliance with stringent regulatory expectations. Aseptic filling equipment are sometimes vital.

Cosmetics: need equipment that retain aesthetic appeal and stop spills. specific volume Command and Mild managing are important.

foods and Beverage: will need devices that happen to be quick to scrub and sanitize, usually requiring chrome steel development to satisfy hygiene needs.

chemical substances: Necessitate machines built from corrosion-resistant components and equipped with safety features to guard staff.

own Care: gain from versatile machines which will handle a range of liquid viscosities and container styles.

Before making a order, thoroughly assess your unique desires and pick a product that's customized on your industry software. look at variables for example filling precision, velocity, versatility, and relieve of routine maintenance.

The future of automatic filling is vivid, with improvements regularly enhancing effectiveness and accuracy. By diligently analyzing your needs, picking out the ideal liquid filling device for sale, and partnering that has a highly regarded liquid filling device producer, you are able to enhance your manufacturing processes, enhance your output excellent, and accomplish sustained good results in the aggressive Market. Embrace automation and invest in the way forward for your enterprise these days.

Edward Furlong Then & Now!

Edward Furlong Then & Now! Josh Saviano Then & Now!

Josh Saviano Then & Now! Seth Green Then & Now!

Seth Green Then & Now! Danielle Fishel Then & Now!

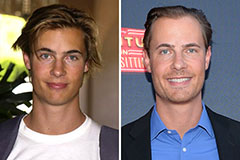

Danielle Fishel Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now!